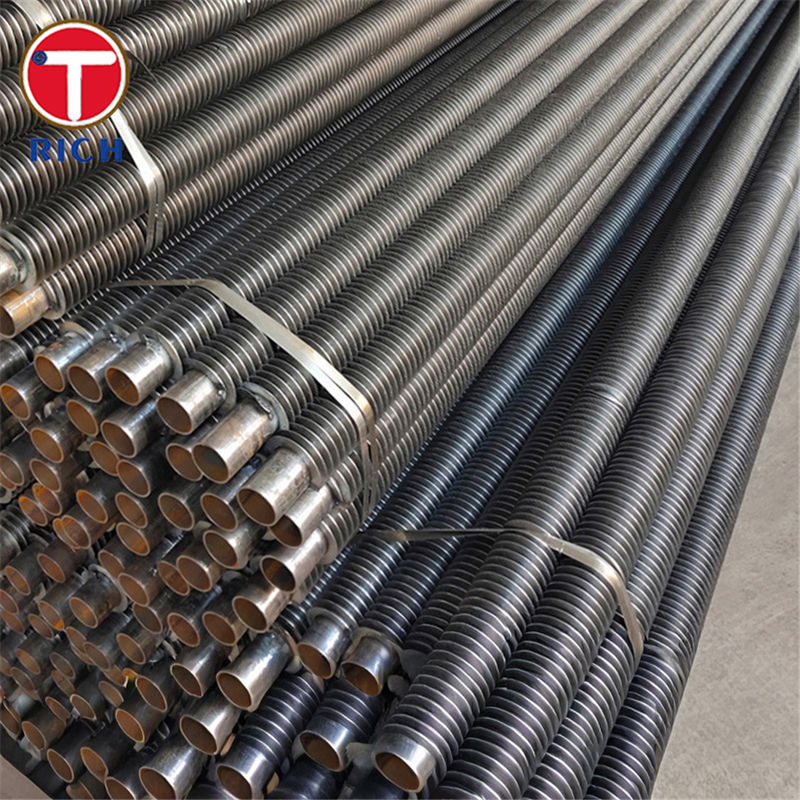

L tubo de aleta de aleación de acero espiral herida tubo de aleta sin costura para el intercambiador de calor de aire

Descripción del material

Este producto es un tubo de aleta espiral de tipo L de cuerda de tensión construido sobre un tubo de calderas/cambio de calor de aleación de acero sin costura Cr·Mo. El tubo base se suministra generalmente en grados como ASTM A213 T11/T22,En el caso de los productos de la categoría N1 y N2, el valor de los productos de la categoría N2 será el mismo que el valor de los productos de la categoría N3., JIS G3462 STBA22 o GB 5310 12Cr1MoVG, todos diseñados para el servicio de presión a temperatura elevada en calderas y intercambiadores de calor refrigerados por aire.

La banda de aleta de aluminio o de cobre se forma en frío en un perfil de L y se enrolla helicoidalmente bajo tensión alrededor del tubo de acero aleado de modo que la aleta de pie se presione firmemente contra la superficie del tubo.proporcionando una aleta espiral continua con buen contacto térmico y protección parcial de la pared del tubo contra la corrosión ambiental.

Especificaciones

Tubos de base

-

Opciones de material (sin costura, acero aleado):

-

Se aplicarán los siguientes requisitos:

-

En el caso de los productos de la categoría N1 y N2, el valor de los productos de la categoría N2 será el valor de los productos de la categoría N3.

-

JIS: STBA22 hasta JIS G3462

-

Se aplicará el método de cálculo de las emisiones de gases de efecto invernadero.

-

Diámetro exterior: aproximadamente 16 ′′50.8 mm (5⁄8" ′′2")

-

espesor de la pared: dependiente de la aplicación, normalmente 2 ∼8 mm para los enfriadores de aire

Geometría de las aletas(apenas las aletas de tipo L)

-

Tipo de aleta: pie en L, en espiral

-

Material de las aletas: aluminio o cinta de cobre

-

Altura de las aletas: hasta unos 16,5 mm

-

El espesor de las aletas: ~0,4 ∼0,6 mm (≈0,015 ∼0,020")

-

Punto de aleta: desde aproximadamente 2,1 mm (≈12 FPI) hacia arriba, optimizado por tarea

Rango de funcionamiento

-

Diseñados para el servicio en el lado del aire donde la temperatura de las aletas es típicamente de hasta unos 150 ∼230 °C, dependiendo del material de las aletas y de su función

-

Los grados de tubos de aleación base soportan temperaturas de metal mucho más altas en el lado del fluido, en línea con sus estándares de caldera/tubo a presión (normalmente clase 500-580 °C para aceros Cr Mo en uso de código).

Características clave

-

Alta densidad superficial de transferencia de calor

-

Contacto térmico eficiente entre aletas y tubos

-

Cuerpo de acero de aleación para el servicio de alta temperatura y presión

-

Los grados de tubos de aleación de CrMo como T11, T22, 13CrMo4-5, STBA22 y 12Cr1MoVG proporcionan una alta resistencia a la ruptura por arrastramiento.buena resistencia a la oxidación y soldabilidad para el servicio de calderas y intercambiadores de calor refrigerados por aire.

Nuestras ventajas

A continuación se presentan varias preocupaciones que los compradores de tubos con aletas refrigerados por aire plantean comúnmente, y cómo este producto está posicionado para abordarlas.

1¿Las aletas se mantendrán apretadas bajo temperatura y comenzarán a detener el ciclo?

-

Las aletas de cuerda de tensión de pie en L utilizan una tensión de enrollamiento controlada para que el pie de la aleta esté firmemente sentado en la superficie del tubo, manteniendo el contacto durante el ciclo de temperatura normal.

-

Para los núcleos de aleación de acero, combinamos el material de las aletas y la temperatura de diseño: el tipo L se utiliza cuando las temperaturas de las paredes de las aletas están en el rango moderado (aproximadamente hasta 150 ∼ 230 °C) y las descargas térmicas no son graves.Para condiciones más duras, podemos aconsejar sobre tipos de aletas alternativos (LL / KL / incrustados) basados en las mismas aleaciones Cr Mo.

2¿Es el tipo L el equilibrio adecuado entre el rendimiento y el coste de mi refrigerador de aire?

-

Los tubos con aletas tipo L se encuentran entre las soluciones de aleta espiral más rentables,frecuentemente elegido cuando el presupuesto y el área de superficie por costo son clave y las temperaturas de funcionamiento están en el rango típico de enfriador de aire en lugar de la tarea extrema del horno.

-

Al aumentar el área exterior, un solo tubo con aletas puede reemplazar varios tubos desnudos, reduciendo el tamaño del haz, la potencia del ventilador, el acero estructural y el CAPEX general del proyecto, manteniendo la carga térmica requerida.

3¿Cómo se maneja la corrosión y la vida útil de los refrigeradores de aire exterior?

-

El tubo del núcleo de acero aleado proporciona una fuerte resistencia a la oxidación a altas temperaturas y a la corrosión por el lado del vapor; en el lado del aire,La aleta de pie en L protege parcialmente la pared del tubo de la exposición directa a la atmósfera.

-

Los materiales de aletas (aluminio o cobre) y las superficies metálicas o recubiertas opcionales se pueden seleccionar para adaptarse a las atmósferas costeras, industriales o ligeramente corrosivas.Donde predominan el aire húmedo o las atmósferas agresivas, podemos pasar a LL/KL aleta o de acero inoxidable base de tubo / aleta combinaciones para una mayor vida.

4.¿Cumplirá el material del tubo mis requisitos de código y trazabilidad?

-

Ofrecemos tubos de aleación de CrMo en calidades estándar para calderas/intercambiadores de calor: ASTM A213 T11/T22, EN 10216-2 13CrMo4-5, JIS G3462 STBA22 y GB/T 5310 12Cr1MoVG,con certificados de ensayo de molino según la norma EN 10204 (normalmente 3.1) y la trazabilidad total del número de calor.

-

Los ensayos no destructivos (corriente de remolino o ultrasonidos), los ensayos hidrostáticos y la inspección dimensional pueden especificarse para que coincidan con los planes de calidad del cliente para el servicio crítico de intercambiadores de calor refrigerados por aire.

Composición química

| Grado / estándar |

C. Las |

Sí, sí. |

En |

P (máximo) |

S (máximo) |

Crónica |

¿ Qué pasa? |

V. |

| Se aplicarán los siguientes requisitos: |

0.05 ¢0.15 |

0.50 ¢1.00 |

0.30 ¢ 0.60 |

0.025 |

0.035 |

1.00 ¥1.50 |

0Es un calibre.44.65 |

¿Qué quieres decir? |

| Las especificaciones de la norma ASTM A213 T22 |

0.05 ¢0.15 |

≤ 050 |

0.30 ¢ 0.60 |

0.025 |

0.025 |

1.90 ¢2.60 |

0.87 ¢1.13 |

¿Qué quieres decir? |

| En el caso de los productos que no estén sujetos a restricciones de seguridad, se aplicará la norma EN 10216-2 13CrMo4-5 (1.7335). |

0.10 ¢ 0.17 |

≤ 035 |

0.40 ¢ 0.70 |

0.025 |

0.010 |

0.70 ¢1.15 |

0.40 ¢ 0.60 |

¿Qué quieres decir? |

| Se aplicará el método de cálculo de las emisiones de gases de efecto invernadero. |

≤ 015 |

≤ 050 |

0.30 ¢ 0.60 |

0.035 |

0.035 |

0.80 ¢1.25 |

0.45.0. ¿Qué quieres decir?65 |

¿Qué quieres decir? |

| Se aplicarán las siguientes medidas: |

0.08 ¢0.15 |

0.17 ¢ 0.37 |

0.40 ¢ 0.70 |

0.025 |

0.010 |

0.90 ¢1.20 |

0.25 ¢ 0.35 |

0.15 ¢0.30 |

Propiedades mecánicas

| Grado / estándar |

Resistencia a la tracción Rm (MPa) |

Fuerza de rendimiento Re / Rp0.2 (MPa) |

Elongación A (%) |

Dureza (típica) |

| Se aplicarán los siguientes requisitos: |

≥ 415 |

≥ 220 |

≥ 30 años |

≤ 85 HRB |

| Las especificaciones de la norma ASTM A213 T22 |

≥ 415 |

≥205 años |

≥ 30 años |

≤163 HBW |

| EN 10216-2 13CrMo4-5 (t ≤ 16 mm) |

450 ¢ 600 |

≥ 300 |

≥ 19 años |

El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de efecto |

| Se aplicarán las siguientes medidas: |

≥410 |

≥205 años |

≥ 30 años |

¿Qué quieres decir? |

| Se aplicarán las siguientes medidas: |

470 ¢ 640 |

≥255 |

≥ 21 años |

~ 135 ¢ 195 HBW |

Normas aplicables

Las condiciones de las pruebas de calidad

-

ASTM A213 / ASME SA213 ¢ Calderas, supercalentadores y tubos de intercambiadores de calor sin costuras de aleación ferrítica y austenítica (por ejemplo, T11, T22).

EN (Europa)

-

EN 10216-2 Tubos de acero sin costuras para uso a presión, de acero no aleado y de acero aleado con propiedades especificadas para temperaturas elevadas (13CrMo4-5).

-

EN 10028-2 / EN 10222-2 ¢ Productos planos y forjados con propiedades especificadas de temperatura elevada, utilizados para combinar cabeceras y colectores.

JIS (Japón)

Gran Bretaña (China)

GOST (equivalentes de Rusia / CEI)

Áreas de aplicación

Rango de aplicaciones generales

Los tubos de aleta espiral de aleación de acero tipo L se utilizan en intercambiadores de calor refrigerados por aire y gas a líquido donde un fluido de proceso caliente dentro del tubo se enfría con aire ambiente o gas de proceso en el lado de aleta.Son especialmente comunes donde el agua es escasa o cara y los refrigeradores de aire son preferidos a los refrigeradores de agua de concha y tubo.

Industrias y posiciones típicas en el sistema

-

Producción de energía (termal, nuclear, geotérmica)

-

Condensadores refrigerados por aire y paquetes de tubos con aletas para condensación de vapor

-

Precalentadores de aire de caldera y bobinas de economizadores

-

Refrigeradores de hidrógeno generadores y refrigeradores de aceite lubricante (lado del aire)

-

Instalaciones de petróleo, gas y petroquímica

-

Refrigeradores de aletas de aire para unidades de descarga del compresor, deshidratación de gas y fraccionamiento

-

Condensadores aéreos y enfriadores de productos en refinerías

-

Refrigeradores de gas a aire y de líquido a aire de sistemas de encendido y de servicios públicos

-

Fabricación de productos químicos y fertilizantes

-

Refrigeradores de aire de proceso en unidades de amoníaco, urea y ácido nítrico

-

Refrigeradores de recuperación de calor en plantas de oxidación y de polímeros

-

Aire acondicionado, secado y industria general

-

Las bobinas de tubos de aleta en grandes unidades de manipulación de aire y climatización industrial

-

Calentadores de aire para secadores por rocío, hornos y secadores de gas de proceso

-

Intercambiadores de tubos de aletas compactos en equipos OEM y refrigeradores envasados

P: ¿ Es usted una empresa comercial o un fabricante?

R: Fabricante, también puede hacer comercio.

P: ¿Cuánto dura su plazo de entrega?

R: En general, es de 10-15 días si las mercancías están en stock, o es de 30-40 días si las mercancías no están en stock,

Es según la cantidad.

P: ¿Proporciona muestras? ¿Es gratis o extra?

R: Sí, podríamos ofrecer la muestra de forma gratuita, pero necesitamos pagar el costo del flete.

P: ¿ Cuáles son sus términos de pago?

R: Pago <=2000USD, 100% por adelantado. Pago>=2000USD, 30% T/T por adelantado, saldo antes del envío.

Si tiene alguna otra pregunta, no dude en ponerse en contacto conmigo.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!